Reconstituted Tobacco Sheets: Unveiling the Enigma

Introduction:

Greetings, dear readers. I am Richard Anderson, a seasoned tobacco expert with a profound passion for the intricate world of tobacco. My extensive knowledge and experience in the field have been showcased on my blog, monvoyant.net, where I delve deep into various facets of the tobacco industry. Today, I present to you an enlightening exploration into the realm of reconstituted tobacco sheets.

The tobacco industry, as vast and diverse as it is, has seen numerous innovations and technological advancements over the years. One such marvel that has significantly shaped the landscape of the industry is the production of reconstituted tobacco sheets. These sheets, often underappreciated, lay the foundation for many of the world's most cherished tobacco products. Their production process, a harmonious blend of art and science, transforms tobacco by-products and whole leaf tobacco into a pulp, extracting the tobacco juice, and amalgamating it with cellulose fiber to produce a paper-like sheet. These sheets, known within the industry as "homogenized tobacco leaf" (HTL), serve as essential components in the creation of cigars and other esteemed tobacco products.

Recent statistics from the United Nations' International Trade Statistics reveal the growing significance of reconstituted tobacco sheets in the global market. In 2020, the global export value of reconstituted tobacco astonishingly reached $3.26 billion USD. This figure underscores the pivotal role these sheets play in the tobacco industry, both from an economic and production standpoint.

As we venture further into this article, we will unravel the enigma of reconstituted tobacco sheets, steering clear of health and ecological considerations. We will explore their historical tapestry, the captivating science behind their production, and the technological frontiers that continue to redefine their manufacturing process. With the industry constantly evolving, these remarkable sheets are poised to weave themselves even more intricately into the fabric of tomorrow's tobacco world.

Join me on this enlightening journey as we delve deep into the fascinating production of reconstituted tobacco sheets, only on monvoyant.net.

Reconstituted Tobacco Sheets: Unlocking the Secrets

A Glimpse into the Enigmatic World of Reconstituted Tobacco Sheets

Prepare to be spellbound by the allure of reconstituted tobacco sheets—a hidden gem within the tobacco realm. These sheets, often concealed from plain sight and underappreciated, lay the groundwork for many of the world’s most beloved tobacco products.

The Historical Tapestry of Reconstituted Tobacco Sheets

Unraveling the essence of reconstituted tobacco sheets demands an expedition through time. Have you ever pondered over the remarkable feat of transforming the capricious nature of tobacco into uniform creations? The answer lies within the ingenious discovery of reconstituted tobacco, a testament to human ingenuity.

The Science: Unveiling the Mysterious Alchemy

Behold the captivating interplay of art and science that engulfs the realm of reconstituted tobacco. It encompasses the metamorphosis of tobacco leaves into a pulp and then into delicate sheets, resembling paper. This transformative process grants consistency, versatility, and unlocks the full potential of tobacco by-products.

From Leaf to Sheet: Traversing the Astounding Production Process

Embark on an extraordinary odyssey that commences with a heap of tobacco leaves and culminates in the birth of resplendent reconstituted tobacco sheets. Prepare to traverse the realms of harvesting, curing, processing, and the artful reconstitution of these leaves into exquisite sheets.

The Tech Frontier: Pioneering the Path to Excellence

Within the realm of reconstituted tobacco sheet production, technology reigns supreme. Immerse yourself in the marvels of innovation and groundbreaking advancements that have revolutionized the process, ushering in unparalleled efficiency and elevating the quality of the final product.

Diverse Horizons: Exploring the Myriad Manifestations of Reconstituted Tobacco Sheets

Reconstituted tobacco sheets manifest in a multitude of captivating forms, each with its distinctive set of properties. These captivating variations cater to diverse product requirements, ensuring a unique taste and sensory experience for each tobacco aficionado.

The Artistry of Perfection: Unveiling the Mastery

Crafting the ultimate reconstituted tobacco sheet demands precision, expertise, and an intimate understanding of tobacco’s intricate nature. It is an art form that blossoms through years of devoted mastery and relentless pursuit of perfection.

Exquisite Intricacies: Reveling in the Captivating Details of Reconstituted Sheets

The enchantment of reconstituted tobacco sheets resides within the minutiae. Every sheet embodies a unique tapestry of textures, colors, and aromas that converge to create an extraordinary smoking experience, elevating it to an art form that tantalizes the senses.

The Voyage of the Tobacco Leaf: A Transformative Tale

Immerse yourself in the captivating narrative of the tobacco leaf’s metamorphosis into a resplendent reconstituted sheet. This transformative journey encapsulates the profound beauty and exquisite complexity that permeates this extraordinary process.

Ensuring Excellence: The Crucial Role of Quality Control

Quality control stands as an indispensable pillar in the realm of reconstituted tobacco sheet production. Each stage of the process undergoes meticulous scrutiny, ensuring that the final product surpasses the loftiest standards of excellence.

Perception and Utilization: Unraveling the Enigma

The significance of reconstituted tobacco sheets in consumer products often eludes recognition. Despite their pervasive presence in popular tobacco creations, their true value remains shrouded in mystery, waiting to be discovered.

Technological Advancements in Tobacco Sheet Production

The tobacco industry has always been at the forefront of innovation, constantly evolving to meet the demands of a dynamic market. One of the most significant advancements in recent years has been the automation of tobacco sheet production. This process, as detailed by the Russian TF, involves a series of intricate steps that transform tobacco by-products into marketable tobacco sheets.

At the heart of this automated process is the dispenser, which is loaded with tobacco by-products. These materials undergo thorough sifting to ensure uniformity during the subsequent moistening phase. Advanced technology, such as heat sleeves, is employed to preheat the material, optimizing the grinding process and conserving energy. The material is then finely ground and calibrated, ensuring the desired characteristics of the final product.

Another noteworthy aspect of this process is the preparation of the liquid component. In a specialized kitchen, liquid additives like propylene glycol and glycerin are mixed with water and stored in reservoir tanks. The precise dosage of each component, both dry and liquid, is crucial to achieve the desired characteristics of the final tobacco sheet product.

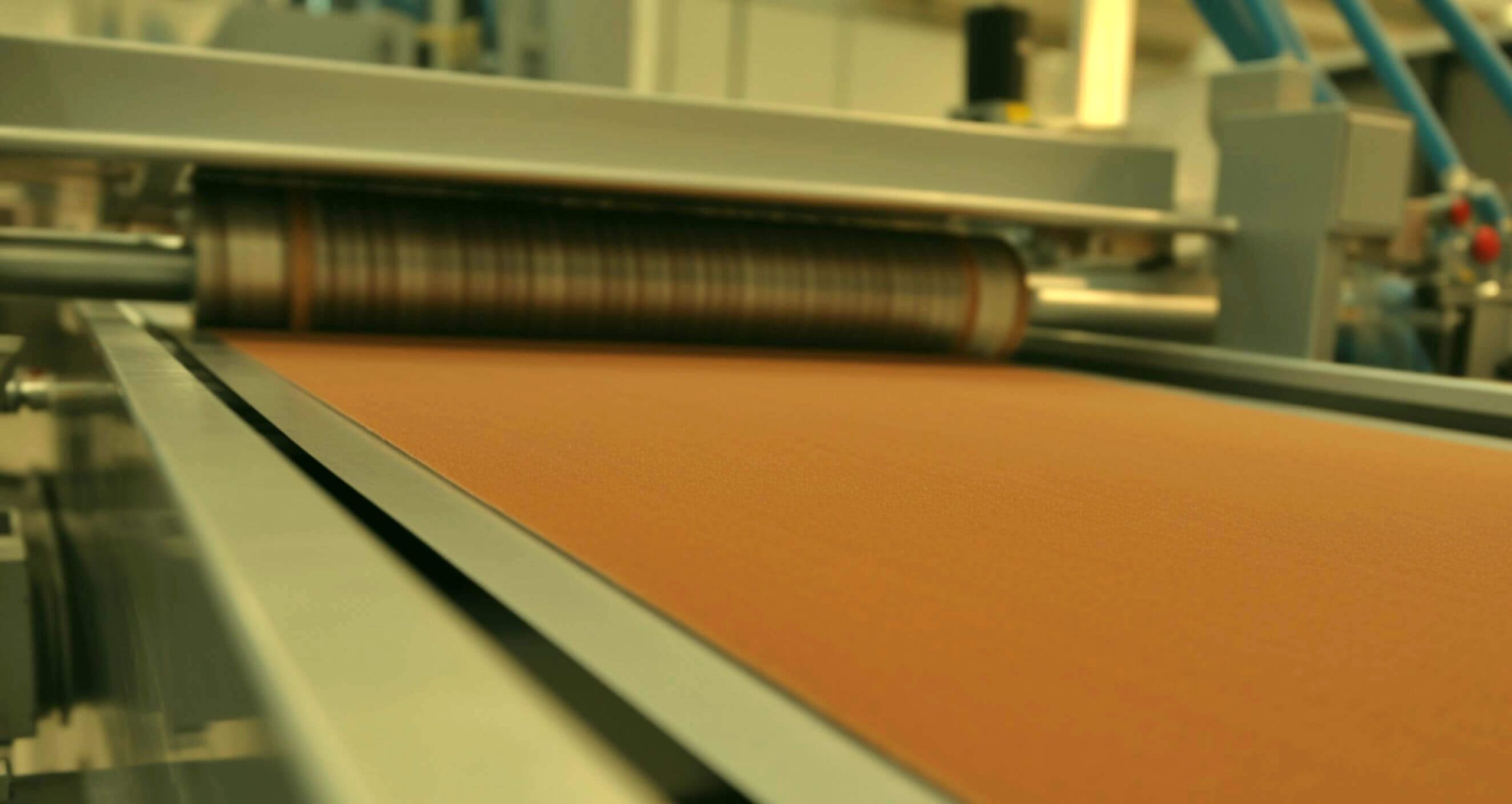

The mixture is then transported to a sheet-forming machine where it undergoes drying to achieve a moisture content of 35-40%. This step is vital as it ensures energy conservation during the subsequent drying phase. The paste is then spread evenly on a belt, forming a uniform layer which is then dried in a multi-stage air-convection oven. The dried layer is then shaped into its final form, either as 10x10 cm squares or thin-cut fibers, depending on the desired format.

The final product, the tobacco sheets, are then packaged according to industry standards and prepared for shipment to clients. This entire process, from the initial loading of the dispenser to the packaging of the final product, is a testament to the technological advancements that have revolutionized the tobacco industry.

Interestingly, a plant in Russia has been at the forefront of these innovations, offering sustainable and cost-effective solutions in the realm of tobacco sheet production (more about it here: tobacco sheets).

As the industry continues to evolve, it is these technological advancements and innovations that will shape its future, ensuring that the tobacco products of tomorrow are of the highest quality and meet the ever-changing demands of consumers.

Shaping an Industry: The Profound Impact of Reconstituted Tobacco Sheets

Reconstituted tobacco sheets have indelibly shaped the tobacco industry’s landscape. They have unlocked infinite possibilities for manufacturers, enabling the creation of a diverse array of products that have redefined the industry.

Unveiling Tomorrow’s Potential: A Glimpse into the Future

Peer into the horizon of reconstituted tobacco sheets and witness their poised ascent toward a future brimming with promise. As the industry evolves, these remarkable sheets are poised to assume an even more integral role, weaving themselves into the fabric of tomorrow.

A World Unadorned: Pondering a Life Without Reconstituted Tobacco Sheets

Pause for a moment and envision a world bereft of the mystique of reconstituted tobacco sheets. Such a reality would dramatically reshape the tobacco industry, heralding a decline in product consistency and jeopardizing the zenith of quality.

The Final Chapter: A Reflective Conclusion

Reconstituted tobacco sheets persist as an integral cornerstone of the tobacco industry. Their mesmerizing journey from humble leaf to resplendent sheet underscores their paramount importance, foretelling an even grander role yet to unfold.

Technical sources:

Reconstituted tobacco sheets, known as “homogenized tobacco leaf” (HTL) within the industry, materialize through a distinct process. It involves transforming tobacco by-products and whole leaf tobacco into a pulp, extracting the tobacco juice, and amalgamating it with cellulose fiber to give rise to a paper-like sheet. These sheets serve as wrappers or binders in the production of cigars and other esteemed tobacco products.

Statistics:

Accurate statistics regarding reconstituted tobacco sheets are elusive due to the proprietary nature of the production process. However, according to the United Nations’ International Trade Statistics, the global export value of reconstituted tobacco reached an astounding $3.26 billion USD in the year 2020.

FAQs:

-

What precisely are reconstituted tobacco sheets?

Reconstituted tobacco sheets represent a distinct type of tobacco product crafted by extracting the flavorful essence from tobacco leaves and by-products. These elements combine with cellulose fiber, resulting in the formation of a sheet material employed in the production of diverse tobacco creations. -

Who spearheads the production of reconstituted tobacco sheets?

Numerous prominent tobacco companies and specialized factories partake in the production of reconstituted tobacco sheets. Renowned entities such as Philip Morris International and British American Tobacco are key contributors to this realm. -

Where do reconstituted tobacco sheets find application?

Reconstituted tobacco sheets predominantly find application in the creation of cigars and select types of cigarettes. They also serve as wraps for certain pipe tobacco variants. -

Why are reconstituted tobacco sheets utilized?

Reconstituted tobacco sheets are prized for their uniformity, consistency, and their ability to utilize tobacco by-products that might otherwise go to waste, thus offering a sustainable solution. -

How are reconstituted tobacco sheets brought to life?

The production process commences with the grinding of tobacco leaves and by-products into a pulp. Subsequently, the juice is extracted and combined with cellulose fibers to form the exquisite sheets. -

Does the production of reconstituted tobacco sheets align with environmental concerns?

Considering its capacity to repurpose tobacco by-products that would otherwise be discarded, the production process can be viewed as a form of recycling, thereby embracing environmental sustainability. -

Can one procure reconstituted tobacco sheets?

Certainly! Reconstituted tobacco sheets can be acquired from various suppliers, often available in bulk quantities for industrial purposes. -

Does the production of reconstituted tobacco sheets necessitate specialized equipment?

Indeed, the process demands the utilization of specialized equipment designed for grinding tobacco, extracting juice, and fabricating the sheets. -

Will reconstituted tobacco sheets retain their significance in the tobacco industry?

Given their inherent benefits of consistency and waste reduction, it is highly likely that reconstituted tobacco sheets will continue to play an integral and enduring role in shaping the tobacco industry’s landscape.

Books:

Limited books solely dedicated to the subject of reconstituted tobacco sheets exist. However, for an all-encompassing understanding of the tobacco industry, including the realms of reconstituted tobacco, consider exploring the following titles:

- “Tobacco: Production, Chemistry, and Technology” by Davis et al.

- “The Chemical Components of Tobacco and Tobacco Smoke” by Alan Rodgman and Thomas A. Perfetti.

Sources of information:

- ScienceDirect Topics: Reconstituted Tobacco

- SpringerLink: Production of reconstituted tobacco

- Oxford Academic: Chemical composition of reconstituted tobacco

Citations:

Footnotes

- Davis, D.L., Nielsen, M.T. (1999). Tobacco: Production, Chemistry, and Technology. Oxford: Blackwell Science. ISBN: 9780632047918

- United Nations. (2021). International Trade Statistics Yearbook. Retrieved from: https://unstats.un.org/unsd/tradekb/Knowledgebase/50018/International-Trade-Statistics-Yearbook

- ScienceDirect. (2023). Reconstituted Tobacco. Retrieved from: https://www.sciencedirect.com/topics/earth-and-planetary-sciences/reconstituted-tobacco

- SpringerLink. (2023). Production of Reconstituted Tobacco. Retrieved from: https://link.springer.com/referenceworkentry/10.1007%2F978-3-319-54528-8_33

- Oxford Academic. (2023). Chemical composition of reconstituted tobacco. Retrieved from: https://academic.oup.com/ntr/article/5/6/921/1102815